Heat the steel to 1 675 degrees fahrenheit in a heat treat furnace or forge and hold it at that temperature for approximately 30 minutes per inch of length to normalize the steel.

4140 steel heat treatment process.

4140hw alloy steel technical data 4140hw meets aisi4140 standards and has improved hardenability and strength in heavier cross sections.

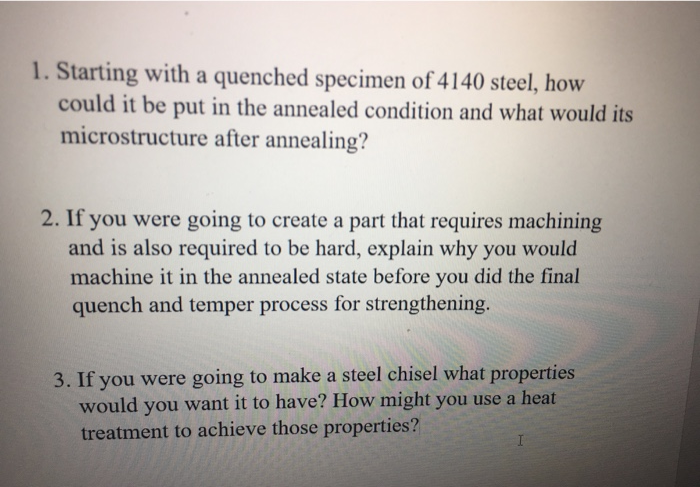

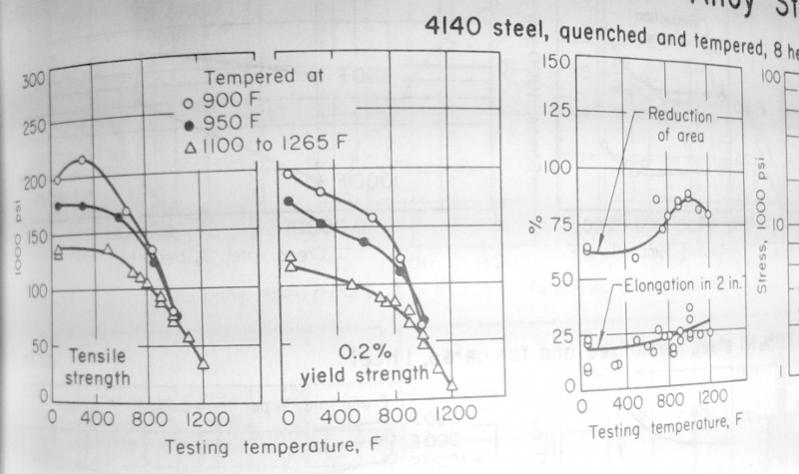

Tempering reheating after quenching will achieve the desired hardness range.

Dry ice is solid at 108 76 f 78 2 c.

1 4140 is an ok die steel but is not recommended for radical shaped dies such as narrow fullering crown and so on.

A dry ice acetone bath typicaly provides 78 f 61 c which is far short of the cryogenic temperature needed for treating steel.

Not all steels are improved by cryogenic treatment.

But it should be tempered for any heavy use.

2 fully hardened 4140 ranges from 54 to 59 hrc.

Sae aisi 4140 alloy steel.

Commercially available aisi 4140 steel has been studied to determine the effect of heat treatment processes on fracture toughness k.

Three types of heat treatments were applied in this work.

Among layman the reason for steel s dominance is usually con sidered to be the abundance of iron ore iron is the principal ingredient in all steels and or the ease by which it can be refined from ore.

3 tempering recommendations from the asm heat treaters guide for 4140 4142 is a minimum of 400 f.

You find 4140hw in a.

Aisi sae 4140 alloy steel can be made into round steel bar flat square steel bar steel.

Fundamentals of the heat treating of steel 11 steel however is by far the most widely used alloy and for averygood reason.

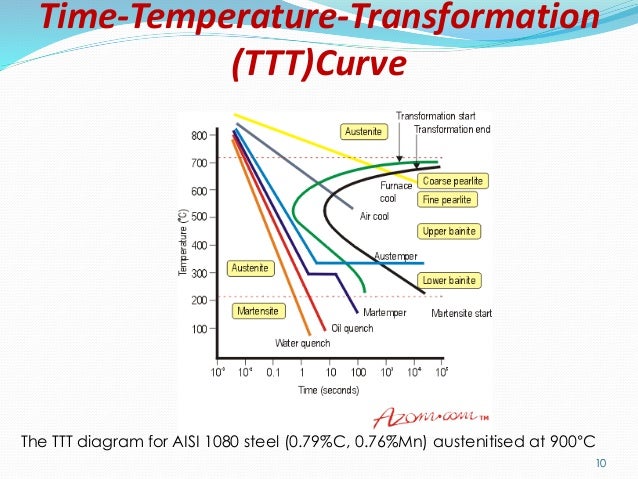

For 4140 steel the recommended heat treatment 1 consists of heating to austenitizing temperature typically 1570 f 855 c followed by oil quenching.

Normalizing removes any stresses within the steel that could create cracks when hardened.

Sae 4140 aisi 4140 steel is a cr mo series chrome molybdenum series low alloy steel this material has high strength and hardenability good toughness small deformation during quenching high creep strength and long lasting strength at high temperature.

.jpg)